When Faith Kipyegon stepped onto the track in Paris wearing Nike’s FlyWeb sports bra, she carried hopes for a sub-four-minute mile. She also wore the future of performance sportswear: a 3D printed garment that challenges decades of athletic apparel design. The convergence of computational design, additive manufacturing, and athletic performance has produced Nike’s first 3D printed sports bra. This development represents a fundamental shift in how performance apparel gets conceived, designed, and manufactured. The FlyWeb addresses problems traditional sports bras have never solved.

Designer: Nike

Traditional sports bras face engineering constraints that limit their effectiveness in enhancing athletic performance. Multiple fabric layers create support but trap moisture and heat, increasing core body temperature by 2-3°F during intense exercise. Seams cause friction during extended movement. Standard manufacturing prevents true customization for individual athletes. Nike’s design team, led by Vice President of Apparel Innovation Janett Nichol, approached these limitations as design opportunities.

The Computational Design Breakthrough

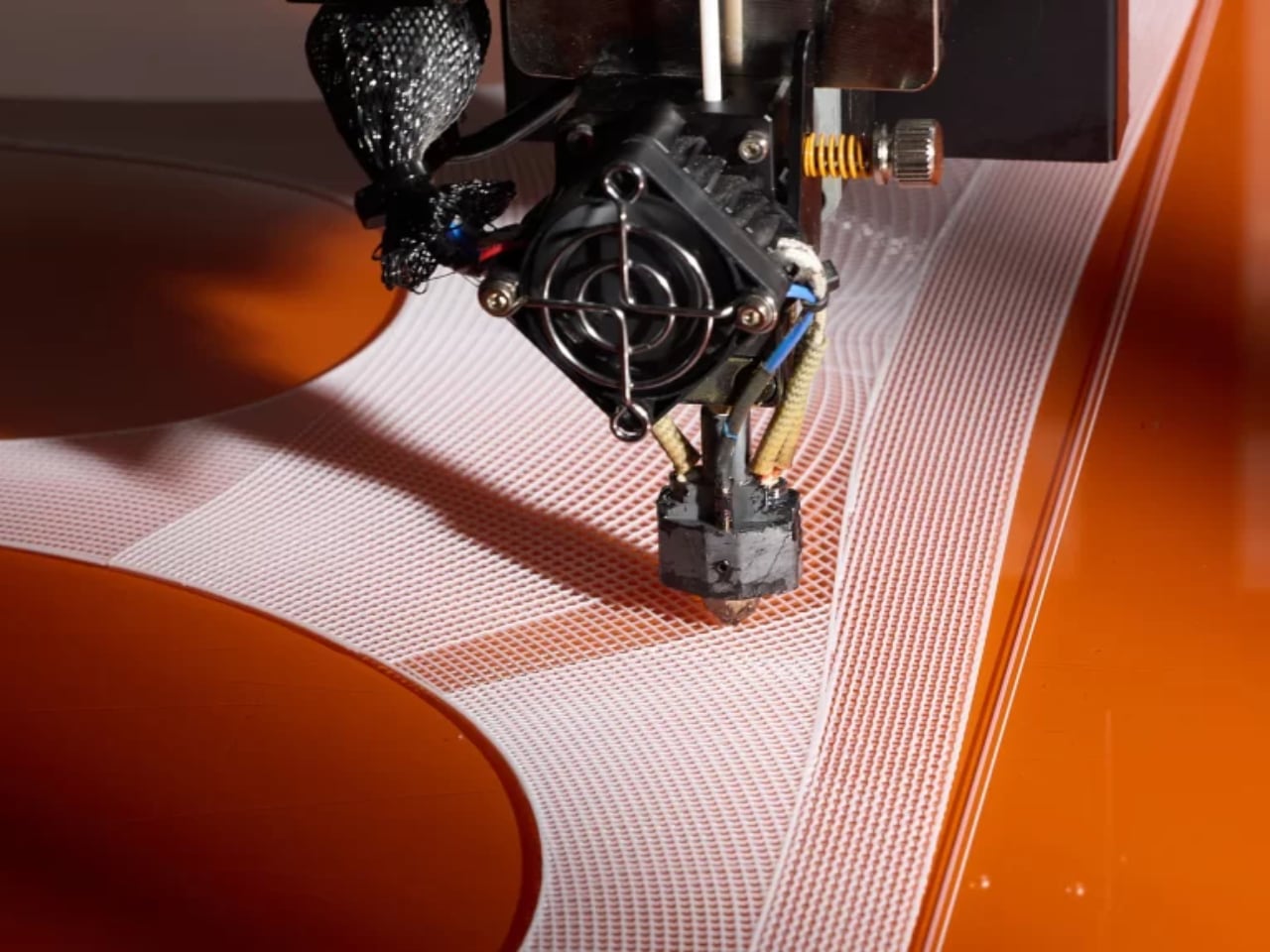

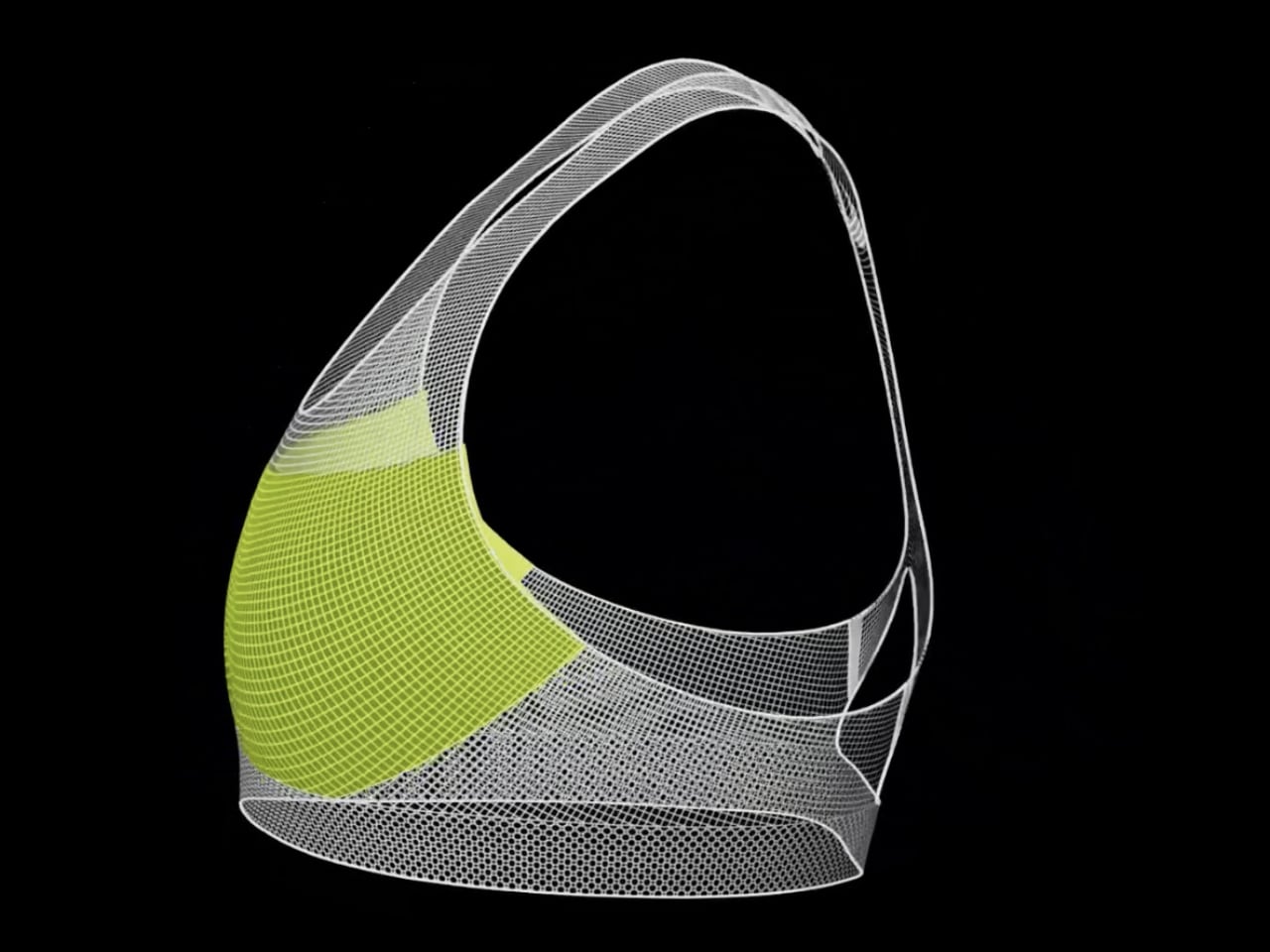

The FlyWeb bra emerges from algorithms, not pattern pieces. Nike’s engineers used computational design to determine optimal material placement for each athlete’s specific needs. The software analyzes stress points, movement patterns, and thermal requirements to generate custom lattice structures. Multiple variables are processed simultaneously, including stress distribution, thermal management, material properties, and manufacturing constraints. The system generates hundreds of design iterations optimized for specific performance criteria.

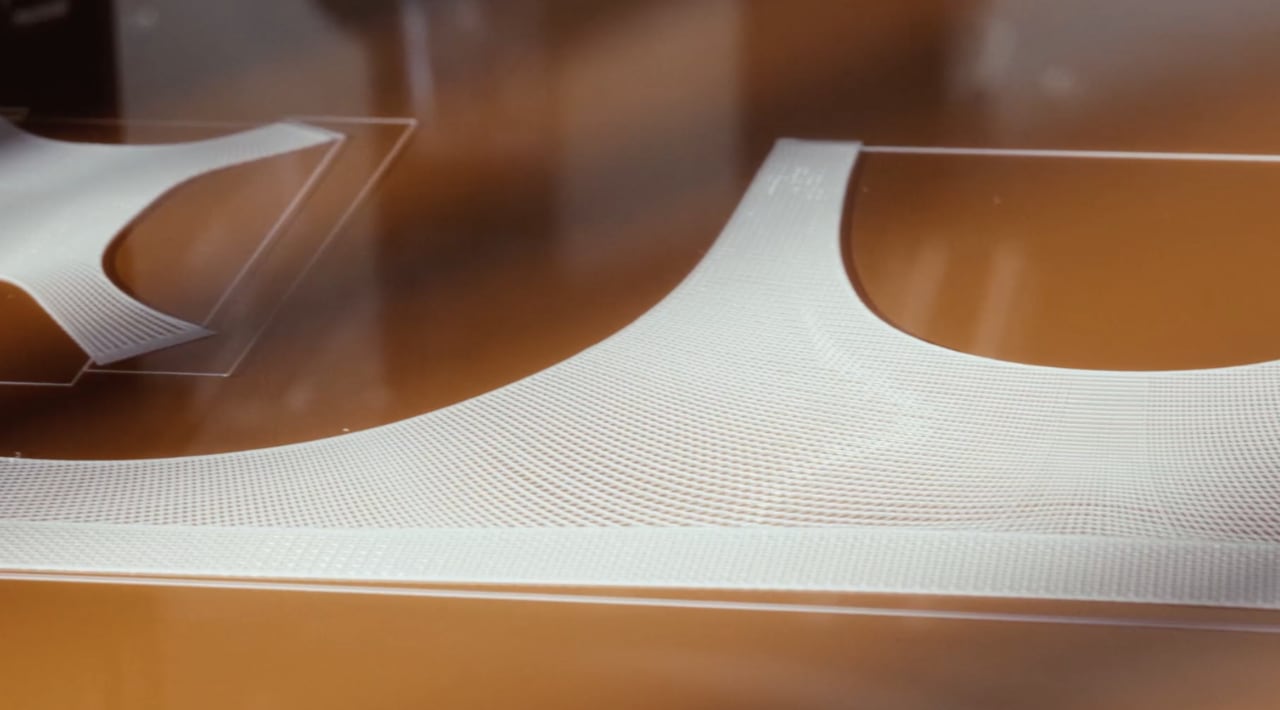

This approach produces garments impossible to create through traditional manufacturing. Variable-density zones provide targeted support where needed, while maximizing airflow in heat-generating areas. The result is a continuous structure that varies in thickness according to support requirements, featuring intricate lattice patterns that enhance breathability while maintaining structural integrity.

Nike selected thermoplastic polyurethane (TPU) as the base material after conducting extensive testing to meet athletic performance requirements. TPU offers flexibility without compromising durability, which is essential for high-impact sports where equipment failure can create problems. The material’s moisture-wicking properties address one of traditional sports bras’ biggest weaknesses, reducing moisture retention by 40% compared to conventional multi-layer designs. The 3D printing process enables variable material density within a single garment. Support zones feature denser TPU structures while flexibility areas maintain lighter patterns.

User Experience and Performance Validation

Faith Kipyegon’s response to the FlyWeb prototype validates the design approach in ways laboratory testing cannot. She described the bra as “friendly,” feedback Nike executives had never received about sports bras. She integrated the prototype into her training routine without prompting, continuing to wear it during sessions in Kenya between testing periods.

Faith Kipyegon Training

“This opens the door to entirely new ideas for how we design and build high-performance apparel going forward. It creates new possibilities for how athletes experience sport through what they wear.” Janett Nichol, Nike VP of Apparel Innovation

Dr. Sarah Martinez, sports biomechanics researcher at Stanford University, notes the significance: “When elite athletes voluntarily adopt new equipment into established routines, it indicates genuine performance benefit. The FlyWeb represents validated development, not technological novelty.” Nike’s testing revealed athletes experienced 25% less chafing during extended training sessions, while core body temperature remained stable during high-intensity workouts.

The development process involved extensive feedback loops with athletes, with prototypes undergoing testing in Kenya with Kipyegon and other distance runners. Each iteration incorporated biomechanical data and subjective comfort assessments. The team discovered that traditional sports bra design assumptions didn’t hold for elite athletes. Support requirements varied significantly based on running gait, body composition, and individual preferences. 3D printing enabled the accommodation of these variables in ways that traditional manufacturing cannot match.

Manufacturing and Industry Change

The FlyWeb project signals broader manufacturing change that extends far beyond Nike’s laboratory. Traditional textile production involves fiber creation, fabric weaving, pattern cutting, and assembly. These multiple stages create waste, require inventory, and limit customization. 3D printing collapses these stages into a single digital-to-physical process, eliminating fabric waste and enabling true mass customization.

The 3D printed wearables market is expanding rapidly, projected to grow from $6.1 billion in 2025 to $13.2 billion by 2035. Nike’s FlyWeb project provides a roadmap for this change, demonstrating how established brands can integrate additive manufacturing into performance product development.

Other major brands are responding. Adidas has developed multiple 3D printed footwear lines, including the Futurecraft 3D and Climacool series, partnering with Carbon for commercial production. Multiple brands, including New Balance and Reebok, have adopted 3D printing for specialized applications. Even luxury fashion is embracing the technology, with New York Embroidery Studio integrating Stratasys 3D printers for haute couture applications.

The broader implications touch on manufacturing localization, supply chain resilience, and economic models. Instead of manufacturing in low-cost regions and shipping globally, brands could operate distributed 3D printing networks closer to consumers. This model offers resilience benefits demonstrated during recent supply chain disruptions, reducing dependency on international shipping while enabling rapid response to demand changes.

Design Philosophy and Future Applications

The FlyWeb bra’s visual impact emerges from functional requirements. Lattice patterns optimize airflow while maintaining structural integrity. Continuous construction eliminates friction points. Every design element serves performance. This approach aligns with modernist design principles where form follows function, achieving visual distinction through honest expression of purpose.

The breakthrough opportunity lies in personalization at scale. 3D body scanning combined with computational design could produce garments tailored to individual body geometry and movement patterns, enabling every athlete to have equipment optimized for their specific requirements. Future iterations could integrate smart textiles, biometric sensors, and responsive materials. Sports bras that monitor heart rate, adjust compression based on activity level, or change thermal properties based on environmental conditions become possible.

Near-term applications extend across industries: compression garments for injury prevention and recovery, climate-adaptive clothing with variable insulation properties, ergonomic workwear designed for specific occupational functions, medical garments with integrated monitoring capabilities, and adaptive clothing for individuals with mobility challenges.

For designers and product developers, the FlyWeb project offers valuable insights that transcend sports apparel. Technology should solve genuine user problems. The 3D printing serves performance enhancement, not novelty demonstration. User feedback drives successful iteration better than laboratory testing alone. Manufacturing method influences design possibilities. By embracing 3D printing’s unique capabilities (variable density, complex geometries, continuous construction), Nike created something impossible with traditional methods.

Interdisciplinary collaboration produces breakthrough development. Material scientists, software engineers, athletes, and designers worked together to solve complex challenges no single discipline could address independently. The result is a product that serves users effectively while opening new possibilities for creative expression in athletic performance design.

Key Questions About 3D Printed Sports Apparel

What makes Nike’s FlyWeb different from traditional sports bras?

FlyWeb uses 3D printed TPU with computational lattice design for continuous construction, 40% better moisture management, and complete customization based on individual athlete body scans and movement analysis.

How does 3D printing improve athletic performance?

3D printing enables variable density zones for targeted support, integrated airflow channels, elimination of chafing-causing seams, and personalized fit optimization impossible with traditional cut-and-sew manufacturing.

When will consumers be able to purchase 3D printed sports apparel?

Nike plans to launch the FlyWeb sports bra commercially by 2028, with additional 3D printed performance apparel categories following as the technology scales for mass production.

As digital fabrication technologies mature, the boundaries between digital and physical creation continue blurring. For designers, the message remains clear: understand your users, solve real problems, and let function guide aesthetic decisions. The FlyWeb project demonstrates that when these principles combine with advanced manufacturing capabilities, the results can change entire industries while serving human performance in ways previously impossible.

The post Nike’s 3D Printed FlyWeb Sports Bra: Design Innovation That’s Changing Athletic Performance first appeared on Yanko Design.

Read More . . .|

| Tweet

| Tweet