Rob Scallon and Mike from Morley Maker just built a hollow-body concrete guitar that actually works, and I’m sitting here wondering what other materials can we just randomly turn into guitars. Sure, concrete guitars do exist in the novelty space (they aren’t a new idea), but they’re typically solid slabs that weigh somewhere between 80 and 90 pounds, which makes them less “playable instrument” and more “sculptural middle finger to ergonomics.” What these two pulled off is different. They engineered a semi-hollow body with 3/8 inch concrete walls, kept the whole thing under 20 pounds (19.8 to be exact), and somehow nailed the intonation without any adjustments. That last part alone tells you everything about how precise the build had to be.

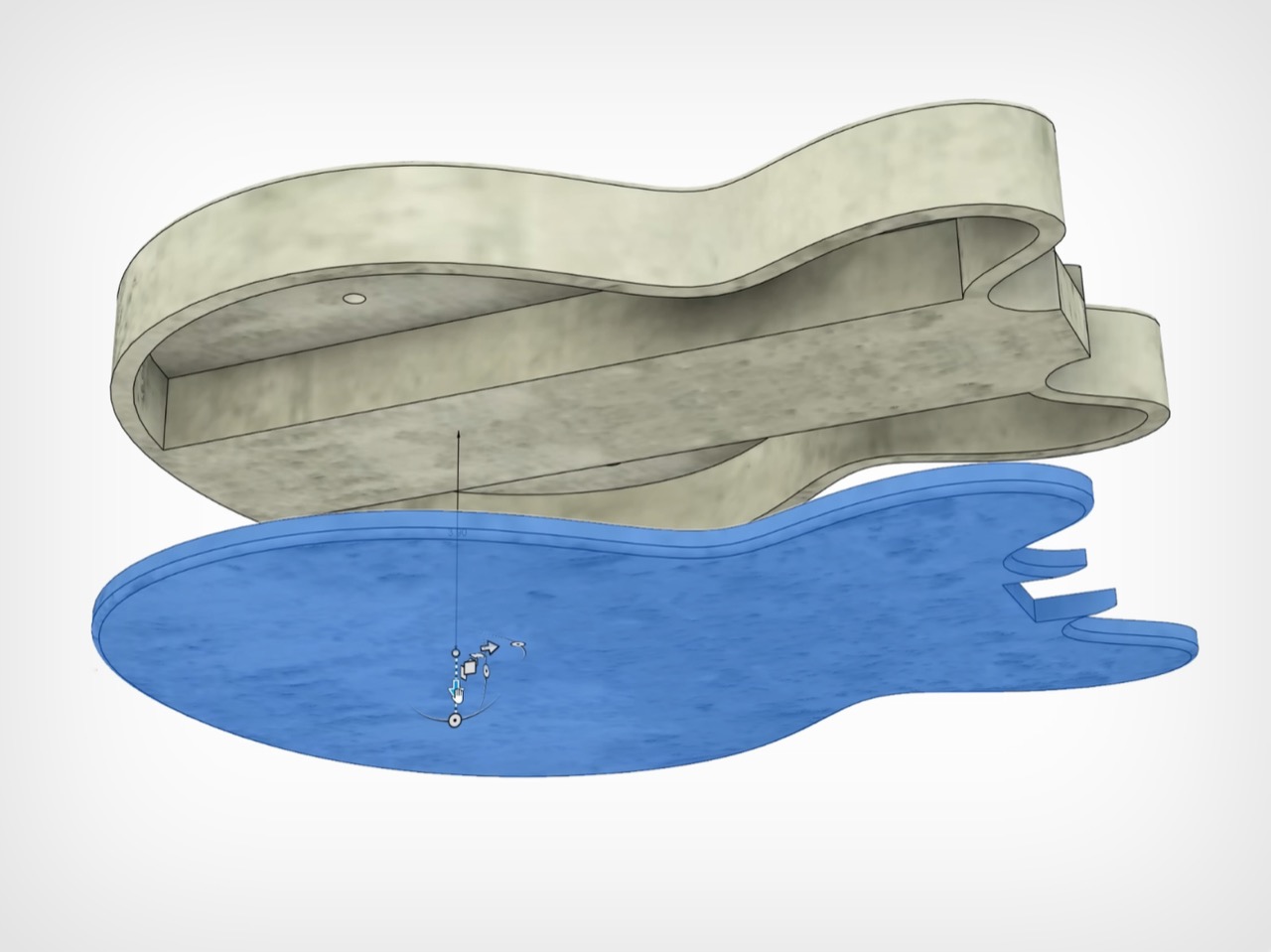

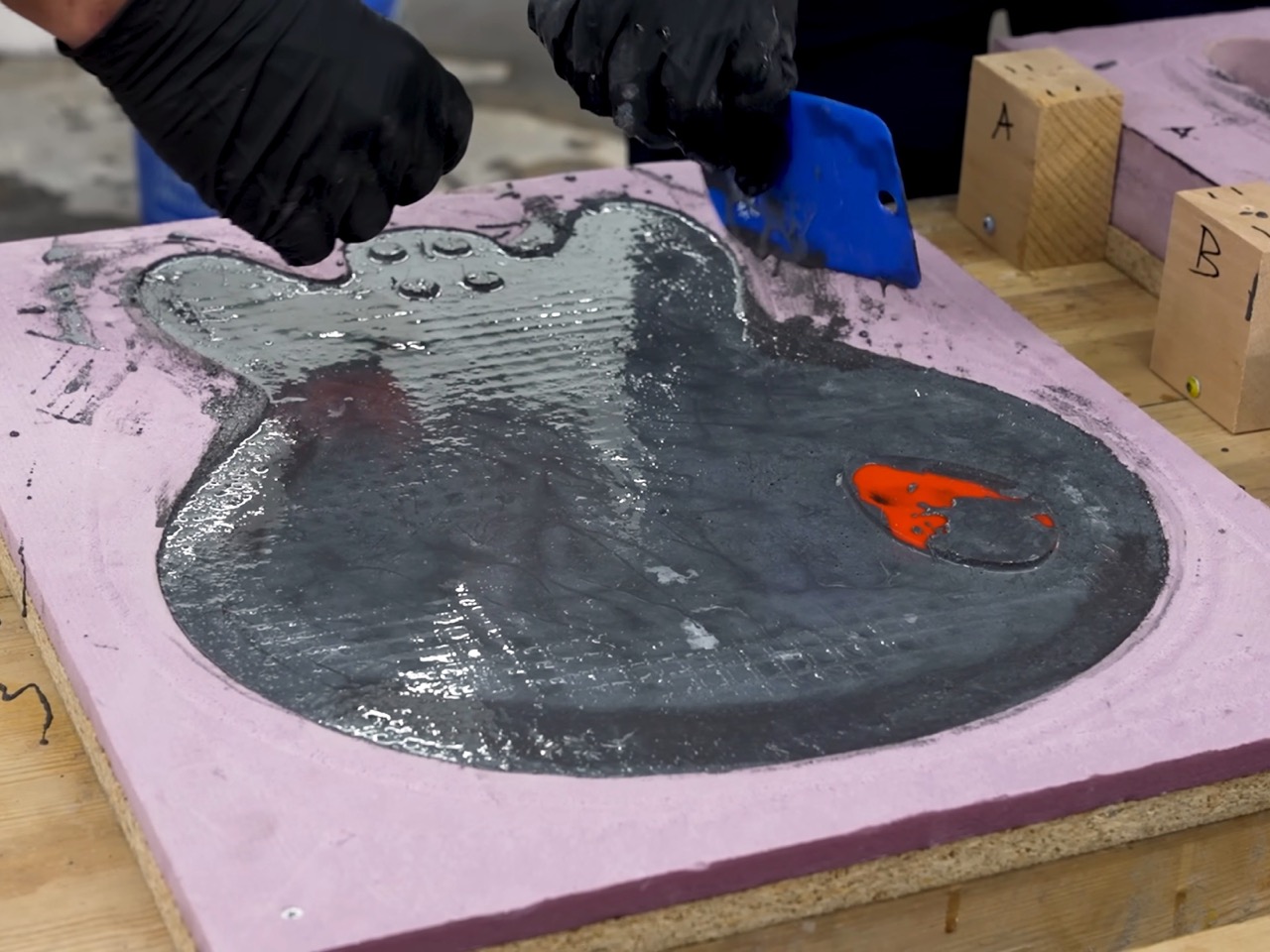

The skepticism going into this was justified. Mike admitted he wasn’t sure the thin walls would hold, and Rob straight-up said he didn’t think it would work. But here’s where the materials science gets interesting. They used a self-leveling concrete mix with plasticizers for viscosity control, then reinforced the whole structure with glass fiber scrim and PVA fibers. The fibers do the heavy lifting here, literally holding the thin concrete together and preventing the kind of catastrophic cracking you’d expect from something this delicate. The embedded wood components stay in the final build, which adds another layer of structural integrity. The form itself was a nightmare of precision: CNC-machined melamine base, 3D-printed F-holes, foam knockouts for the pickup cavities and hollow body chamber, all designed to create exact registration points for neck pocket alignment. Get any of that wrong and you’ve got an expensive paperweight.

Designers: Rob Scallon & Modustrial Maker

The build process looks deceptively simple on paper but the execution window is razor-thin. They’re working with a material that cures to 50% strength in two days and hits 90%+ by day seven, so there’s no room for “let me just adjust this real quick” halfway through. The neck pocket had to be machined so precisely that the finished guitar can be held by the neck alone without the body sliding off… that’s not just tight tolerances, that’s obsessive-level accuracy. They spent 6 to 8 hours on wet sanding alone because concrete at partial cure is unforgiving. Too aggressive and you compromise structural integrity. Too gentle and you’re there all week. The acetone bath for dissolving the foam forms is clever but expensive, and watching them chip away at melamine while hoping the thin concrete walls don’t spiderweb must have been nerve-wracking.

What surprised me is how well this thing actually plays. Zero fret buzz, clean intonation across the fretboard, proper action right out of the gate. The acoustic resonance from the hollow body is minimal but present, which makes sense given that concrete has completely different harmonic properties than wood. The sustain is solid, tone is there, and it handles everything from clean to heavy distortion without falling apart sonically. Rob played it in standard tuning and drop C, and the neck stability actually improved because of the weight distribution. Your shoulder might hate you after a 45-minute set, but your fretting hand gets an unusually stable platform. The weight is the obvious compromise: at nearly 20 pounds, this is double what a heavy Les Paul would clock in at. But compared to the 80-pound concrete bricks that usually show up in these novelty builds, it’s practically svelte.

The cost breakdown is wild when you consider what they achieved. Fifty bucks for the specialty concrete mix, $280 for hardware and electronics, and a free Schecter neck. All in at $400 for what is genuinely the first functional hollow-body concrete guitar. That’s cheaper than plenty of mid-tier production guitars that don’t require you to understand materials engineering, CNC programming, and luthier-level precision. The custom “Creeker” branding is a nice touch, and the nickel humbuckers were the right choice for tone given the density of the body material. Ernie Ball strings are standard but they hold tune exactly as you’d expect, which again speaks to how dialed-in the neck pocket and bridge placement had to be.

The real test was whether this could survive as an actual instrument versus a proof-of-concept that gets one video and then lives on a shelf. Rob’s planning a full playthrough with drums and bass, which means he trusts it enough to track with. That’s the validation that matters. Concrete introduces all kinds of variables that wood doesn’t: different thermal expansion rates, brittleness under tension, unpredictable resonance characteristics. They accounted for all of it. The minor cracking that showed up near the pickup cavities got hidden under the magnets, which is practical problem-solving rather than trying to achieve impossible perfection. The fact that it plays this well without post-build setup is borderline miraculous.

Mike’s comment about platform performance is interesting too. His solar-powered dog house with a swimming pool went viral on Instagram and TikTok but bombed on YouTube, which tells you everything about how algorithm preferences and audience expectations fragment across platforms. YouTube wants longer narratives and build processes. Instagram and TikTok want the immediate visual payoff. This guitar project has both: the satisfying process and the undeniable “holy shit it actually works” moment. The collaboration between a high-profile musician and a maker with serious fabrication chops created something that neither could have pulled off solo. Rob brings the musical credibility and audience. Mike brings the materials knowledge and engineering precision. Together they built something genuinely novel that performs at a level nobody expected. That’s the kind of maker culture output that pushes boundaries instead of just retreading the same novelty builds we’ve seen a thousand times.

The post World’s First Hollow-Body Concrete Guitar Weighs 20 Pounds and Plays Like a Dream first appeared on Yanko Design.

Read More . . .|

| Tweet

| Tweet