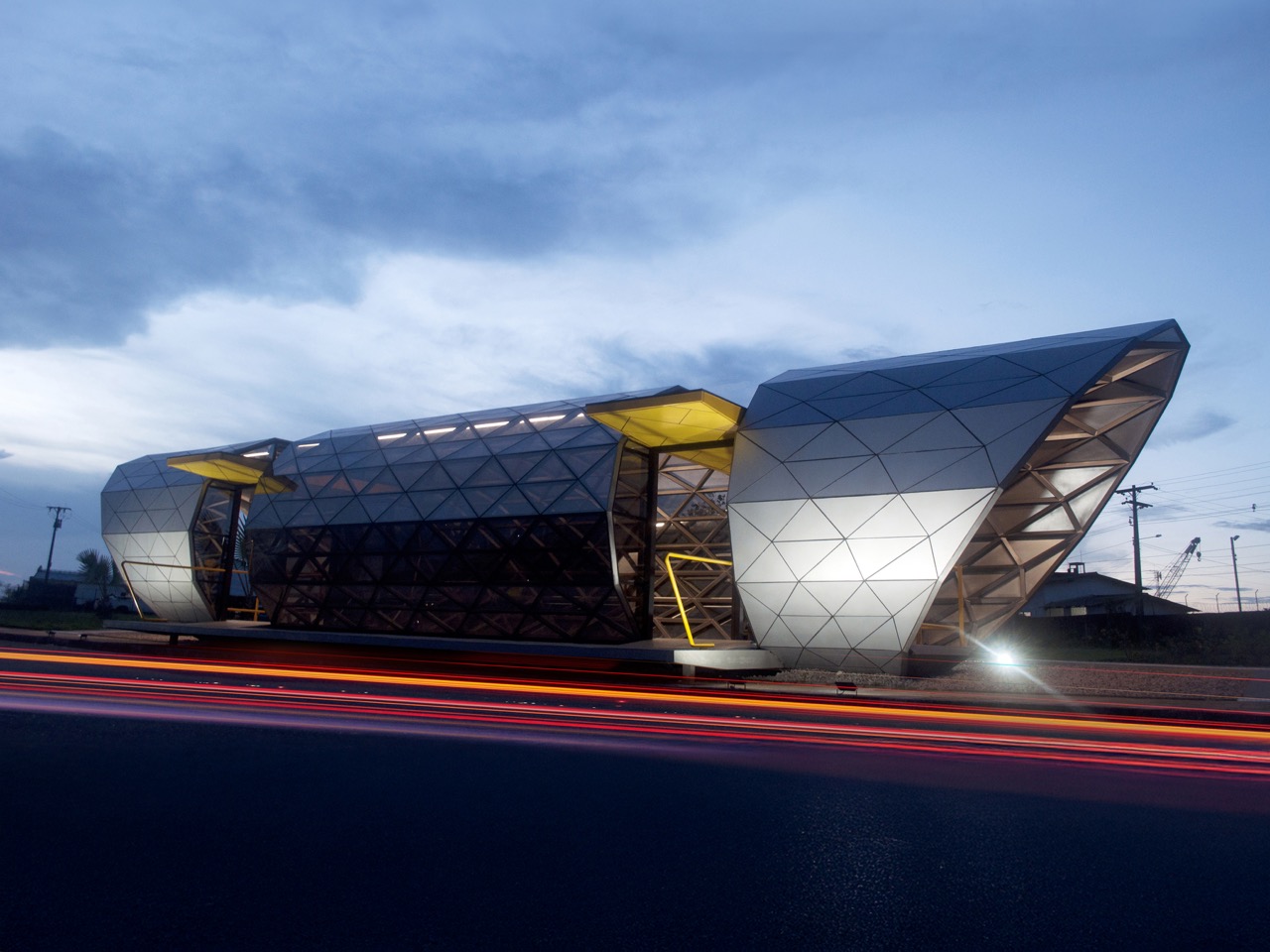

Waiting for a bus shouldn’t feel like purgatory, but in the intense heat and frequent downpours of Brazil’s Amazon region, it often does. Fernando Andrade understood this intimately when he began designing the Amazon Bus Station in Belém, a project born not from architectural ego but from genuine public consultation with the people who would actually use it. They asked for four things: protection from the weather, environmental comfort, durability, and reasonable cost. What they got exceeded every expectation: a soaring, sculptural shelter that treats public transit users as deserving of the same design attention typically reserved for museums and corporate headquarters.

The 16-meter structure, completed in February 2024, wraps passengers in a protective envelope of triangulated steel and reflective glass, its organic curves creating an embracing interior space that feels both sheltering and expansive. Yellow accessibility ramps guide users through a barrier-free environment where natural ventilation, achieved through traditional Amazonian roof fins, keeps air moving without mechanical systems. Shadows from the geometric framework dance across metal benches as daylight filters through the glass skin, creating an ever-changing interior atmosphere that connects occupants to the rhythms of weather and time. The design accommodates everyone, including those with mobility challenges, while pushing what architectural beauty can achieve in public infrastructure.

Designer:

The structural approach here is basically what happens when parametric design actually solves problems instead of just generating Instagram bait. The whole thing is built from 600mm triangular modules, each assembled from 75x3mm quadrangular steel tubes. That triangulation distributes loads efficiently enough that the entire 16-meter span rests on just four support points, which means minimal ground disruption and maximum flexibility for street-level circulation. And they used recycled steel throughout, dropping carbon emissions by 70% compared to conventional construction methods. The numbers matter because this approach could scale. Belém gets this one station, but the fabrication methodology, the material choices, the whole industrial-to-site assembly process translates to other locations dealing with similar climate challenges and budget constraints.

The 8mm laminated glass blocks 99.8% of direct solar radiation, which in equatorial conditions isn’t a nice-to-have feature, it’s the difference between a functional space and a greenhouse. But the clever bit is those ventilation fins at the roof ridge. They’re angled glass louvers that let hot air escape while keeping rain out, basically a stack effect ventilator with zero moving parts and zero maintenance requirements beyond occasional cleaning. No motors failing, no electronics corroding in humidity, no ongoing energy costs. Just heated air rising and escaping through geometry that works with local wind patterns. It’s the kind of solution that feels obvious in hindsight but requires serious environmental modeling to get right.

Nine months from concept to completion, with fabrication happening in a controlled industrial environment using local shipbuilders who know how to work with complex curves and weather-resistant assemblies. They pre-built the structure in three major sections, transported them to site, and only finished the connection joints on location. That level of prefabrication ensures tolerances stay tight and quality control doesn’t depend on field conditions, which matters when you’re dealing with structural silicone joints and precise glass panel alignments. The client, Centro Integrado de Inclusão e Reabilitação, specializes in accessibility infrastructure, so the barrier-free circulation wasn’t an afterthought added to satisfy code. It shaped the entire spatial concept from the beginning.

The real test of any transit infrastructure is whether it changes behavior. A better bus station doesn’t just shelter existing riders, it potentially converts people who currently drive because the bus experience feels too degrading or uncomfortable. Belém’s new station won’t single-handedly transform modal split numbers, but it signals that public transit users deserve environments worth occupying. These details accumulate into an experience that respects users enough to think through their actual needs rather than just checking regulatory boxes. That respect, rendered in recycled steel and high-performance glass, might be the most radical thing about the whole project.

The post This 690 Sq.Ft. Bus Station Cuts Carbon Emissions by 70% Using Recycled Steel first appeared on Yanko Design.

Read More . . .|

| Tweet

| Tweet