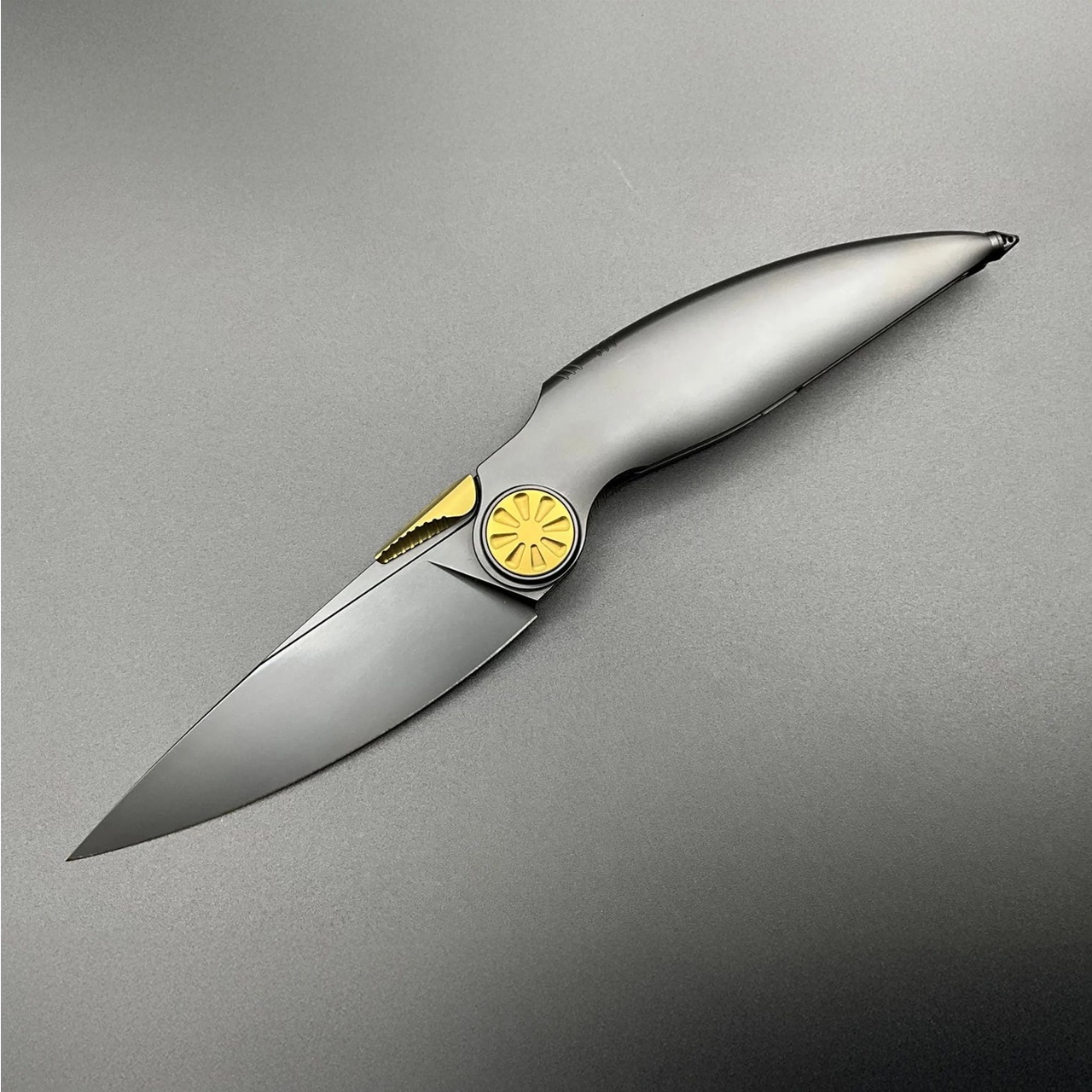

There’s a peculiar tension at work when CNC machines create objects that look grown rather than made. The Rike Predator exists in this liminal space, where five-axis precision milling produces curves that read as biological. Richard Wu has weaponized this contradiction. His knife appears to have evolved rather than been designed, yet every surface betrays the obsessive control of someone who measures in microns.

Designer: Richard Wu / Rike Knife

I keep returning to the handle’s topology. The curves don’t reference any specific natural form, which is precisely why they feel organic. Wu avoided the trap of biomimicry, that lazy design shortcut where everything becomes a leaf or a bone or a seed pod. Instead, he created something that triggers our pattern recognition without satisfying it. The brain reads “living thing” without being able to name what living thing. That ambiguity generates visual tension that more literal designs cannot achieve.

The manufacturing reality makes this even stranger. This handle began as a rectangular billet of 6AL4V titanium, the same alloy bolting together airframes and replacing human joints. Industrial material. Industrial process. Yet the output suggests something pulled from the ocean floor or excavated from amber. Wu has essentially tricked titanium into forgetting what it is.

The Vanishing Act

Most folding knives announce their construction. Screws dot the handle scales. Pivot hardware protrudes. Pocket clips bolt on as afterthoughts. The Predator refuses this transparency. Wu has hidden nearly every piece of evidence that this object was assembled at all.

The presentation side shows nothing but unbroken titanium flowing from bolster to pommel. No screw heads. No seams where separate pieces meet. No liner peeking through. The knife could have been cast from liquid metal or 3D printed as a single unit for all the visual information available. This absence reads as confidence. Wu doesn’t need to show you how clever the engineering is because the engineering has made itself invisible.

What remains visible carries meaning precisely because so much has been eliminated. The pivot, rendered in contrasting gold on the darker variant, becomes a focal point by default. The thumb studs, shaped into sculptural teardrops rather than utilitarian cylinders, register as deliberate design choices rather than functional necessities. When you subtract everything possible, what survives better be worth looking at. Wu understood this calculus.

The frame lock mechanism deserves mention here because it reinforces the vanishing act. Typically a separate component, Wu machined it directly from the handle’s titanium. One less part. One less seam. One less interruption in that flowing surface. The lock becomes the handle becomes the knife. Boundaries dissolve.

Material Honesty and Its Complications

Designers love talking about material honesty, that modernist principle where materials should look like what they are. Titanium should read as titanium. Steel should read as steel. The Predator complicates this framework in productive ways.

The titanium handle is honest about being titanium in its weight, its temperature response, its surface hardness. But its form lies constantly about how titanium typically behaves. The material wants to be sheet metal and structural tubing and medical implants. Wu forced it into something approaching sculpture. The honesty exists at the molecular level while the dishonesty operates at the formal level. Both readings are valid.

The blade tells a simpler story. Böhler M390, a powder metallurgy steel from Austria that knife obsessives treat as holy writ. Exceptional edge retention. Genuine corrosion resistance. The ability to take a working edge sharp enough to push-cut newspaper. At 3.74 inches, the drop-point geometry handles utility tasks without crossing into intimidation territory. This is honest tool steel doing honest tool steel work.

The two-tone gunmetal variant introduces another layer to consider. Gold-finished pivot and thumb studs against dark titanium creates deliberate contrast, a conversation between components that the all-silver version deliberately avoids. Neither approach is more correct. They represent different arguments about how materials should relate to each other within a single object.

The Ritual of Manual Deployment

In an era of assisted opening mechanisms and spring-loaded deployment, the Predator demands something old-fashioned: your direct participation. Those sculptural thumb studs aren’t decorative accidents. They’re the interface between your intention and the blade’s movement.

Opening this knife requires a deliberate act. Thumb finds stud, applies pressure, rotates blade through its arc until the frame lock engages. No flippers throwing the blade open with wrist momentum. No buttons triggering compressed springs. The mechanism is your hand, your muscle memory, your learned technique. Wu has made opening the knife into a small daily ritual, a moment of conscious interaction with an object that rewards attention.

This choice filters the audience. Buyers wanting tactical speed and one-handed drama should look elsewhere. The Predator speaks to people who find satisfaction in deliberate action, who treat their tools as partners rather than servants. The deployment method functions as a values statement encoded in mechanical form.

Value Proposition

Four hundred fifty-five dollars for a knife. Four hundred eighty-five for the darker finish. These numbers require justification beyond brand markup and lifestyle positioning.

The integral construction explains much of the cost. Machining a handle from solid titanium billet wastes enormous amounts of material. The cutting time alone dwarfs what conventional folder assembly requires. Add M390 blade steel, heat treatment, hand finishing, and quality control obsessive enough to satisfy Wu’s standards, and the price begins making sense as simple manufacturing economics.

Whether that manufacturing investment produces equivalent value depends entirely on what you’re buying. As a cutting tool, the Predator performs well without dramatically outperforming knives costing half as much. As a design object, a piece of industrial sculpture you happen to carry daily, the value proposition shifts entirely. Some buyers will use their Predator to break down cardboard and slice apples. Others will mostly just hold it, feeling those curves against their palm, appreciating what happens when someone applies genuine design thinking to the oldest tool category humans possess.

Both groups are buying the same knife. They’re just not buying the same thing.

The post Rike Predator: When Integral Construction Defines the Future of EDC Knife Design first appeared on Yanko Design.

Read More . . .|

| Tweet

| Tweet